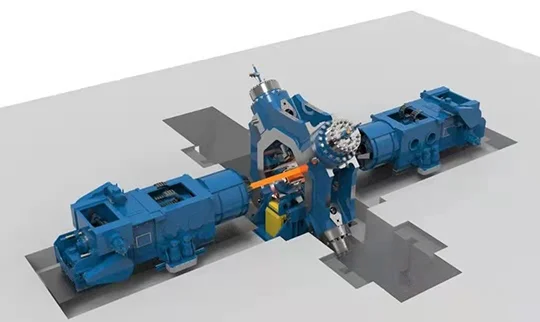

Radial forging is a precision forging process where multiple (2-8) hammers are distributed around the billet, performing high-frequency synchronous forging blows along the axis of the forged billet. The billet rotates while axially feeding, causing it to elongate and thin under multi-head helical stretching and deformation.

Radial forging is suitable for long shaft-type forgings of various shapes, solid or hollow, as well as long, straight hollow shaft forgings with complex internal contours (such as internal threaded holes, internal spline holes, gun barrel rifling, etc.) or very small internal diameters.

As a professional manufacturer of CNC forging equipment, we provide comprehensive service and support to our international clients, covering equipment supply, technical assistance, customized services, and after-sales guarantees.

The main equipment includes: a forging manipulator for handling raw materials, a hydraulic forging press for upsetting and piercing the blank, a forging manipulator for blank transfer and positioning, a radial-axial ring rolling machine for ring rolling, a forging manipulator for finished ring removal, and a straightening press for correcting ring deformation.

Learn More